- Insearch Formulation

- January 14, 2025

- 7:24 am

- No Comments

Third party manufacturing pharma has brought in innovation in the pharmaceutical sector with a lot of opportunities for companies to expand production, improve the quality, and make sure the shipment of medicines is on time. In the run to grab hold of the increasing demand for a reliable healthcare manufacturing sector, third-party pharma manufacturers in India are enlarging their capabilities and experience so that they can meet the global standards. Whether you are still a startup or a company that has been on the market for a long time, having this model knowledge can be an additional piece of information that can certainly help the company positively.

What is Third Party Manufacturing Pharma?

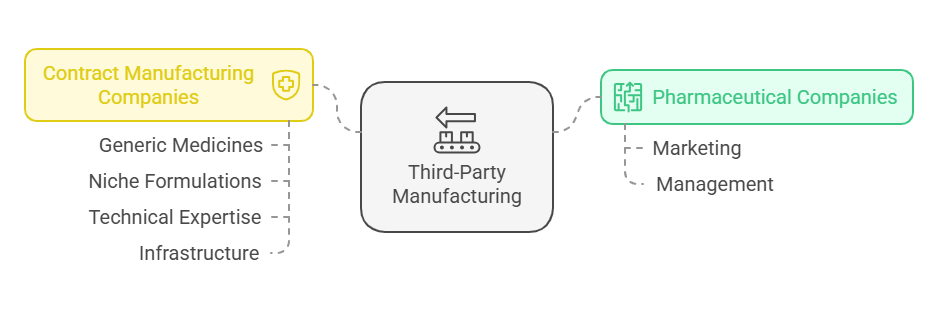

Third party manufacturing pharma is the outsourcing of the production of pharmaceutical products to a third-party manufacturer. This principle enables pharmaceutical companies to pay more attention to marketing and management while at the same time harvesting from specialized manufacturer’s technical expertise and infrastructure. Contract manufacturing pharma companies in India are very important and they play a vital role in meeting the different requirements of the healthcare sector, from generic medicines to niche formulations.

Why Pharma Companies Need Third Party Manufacturing Pharma ?

1. Cost Efficiency

Reduced Capital Investment: Setting up and operating a full-blown production facility is capital-intensive. Third-party manufacturing will eliminate such investments.

Operational Cost Savings: Companies save on labor, raw materials, and maintenance.

2. Focus on Core Competencies

Concentration on R&D and Marketing: Outsourcing manufacturing will allow companies to concentrate on product innovation, research, and marketing instead of production logistics.

Scalability: Pharmaceutical companies can scale up or down according to need, without attendant manufacturing headaches.

3. Expertise and Compliance

Technical Expertise: Third-party manufacturers usually have equipment that produces excellent products using advanced technologies.

Regulatory Compliance: Third-party manufacturers have set up systems to comply with certain specifications, like WHO-GMP, USFDA, and EU.

4. Faster Time-to-Market

Quick Production Setup: Using the already present infrastructure of third-party manufacturers means fast product launches.

Efficient Supply Chains: Due to well-structured practices these manufacturers follow to adhere to production deadlines, time-to-market gets shortened.

5. Product Diversification

Multiple Product Lines: With third-party services, pharma companies can launch various products without investing in specialized manufacturing units for each one.

Access to Specialized Formulations: Third-party manufacturers are able to develop complex formulations that may be challenging for companies of lesser capacities.

Benefits of Third Party Manufacturing Pharma

Third party manufacturing Pharma provides pharmaceutical companies with a plethora of benefits. By outsourcing production, firms can utilize the facilities and expertise of well-established manufacturers. This can translate into cost and efficiency gains. Quality production can be ensured by enforcing strict checks and measures. Third party manufacturing Pharma allows pharmaceutical firms to focus on core activities, which, in turn, enhances creativity and growth within the pharmaceutical world. Below are a few of the common benefits instead:

1. Cost-Effectiveness

Collaborating with the top third party pharma manufacturers in India has become a proven way for companies to save a significant amount in distribution, labor, and equipment. The production of top pharmaceutical companies established as operational efficiencies is done at less cost while maintaining top quality.

2. Scalability

Getting in touch with contract manufacturing pharma companies in India allows businesses to expand their capacity according to demand without the necessity of a considerable capital investment. This adaptability is highly useful in product releases or the seasonal swelling of demand.

3. Expertise and Compliance

Third party pharma manufacturers in India have the technical expertise and resources to adhere to stringent regulatory standards, ensuring that products meet quality and safety requirements. Their compliance with Good Manufacturing Practices (GMP) and other certifications guarantees excellence.

4. Focus on Core Competencies

Outsourcing manufacturing allows companies to pay attention to main skills like research, marketing, and distribution. This split of work helps improve productivity and support business growth.

How Does Third Party Manufacturing Pharma Work?

The process of engaging a third party manufacturing pharma company involves the following steps:

- Product Specification: Specify the product type, formulation, and amount needed.

- Manufacturer Selection: Find trustworthy third party pharma manufacturers in India that have the right certifications and skills.

- Agreement Signing: Write and confirm a contract that states terms, timelines, and duties.

- Production Initiation: The manufacturer gets raw materials and starts making the product as per the agreed details.

- Quality Assurance: Carry out strict quality inspections to meet regulatory rules.

- Delivery: Get the completed products ready to be distributed.

Top Third Party Pharma Manufacturers in India

India is home to numerous reputable third-party manufacturing pharma companies offering diverse services:

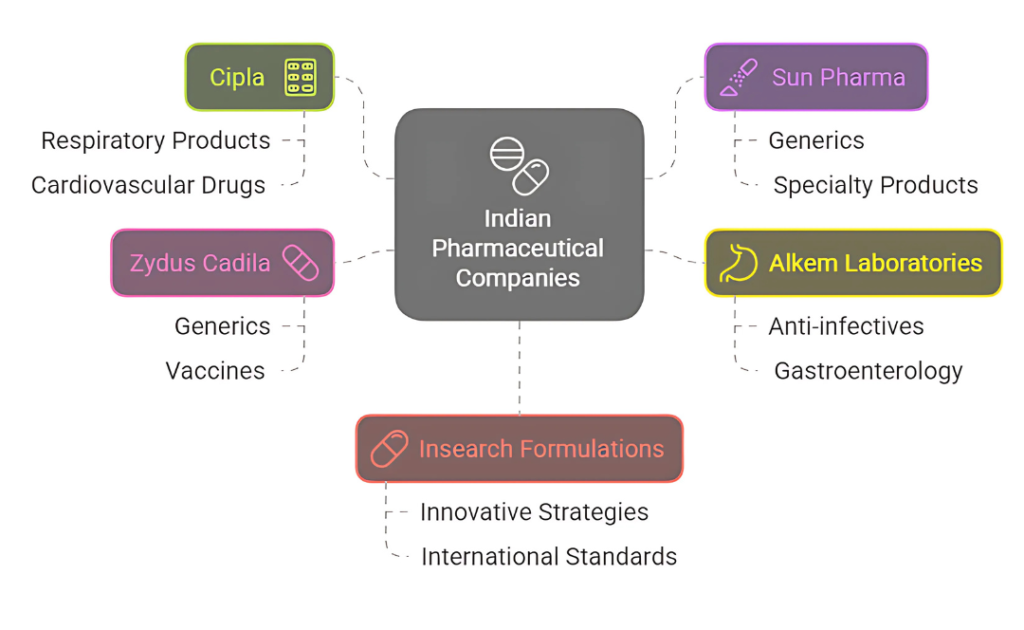

- Insearchformulation: Founded in India, Insearch Formulations Private Limited is a newly established pharmaceutical company carving a niche in the Indian market with its range of affordable, high-quality drugs. It covers various major therapeutic areas in the health industry and therefore has focused on innovative strategies and access to quality medications as well as importing them by international standards to meet the needs of the different markets.

- ANTIBIOTICS

• CAPSULE

• CARDIAC AND DIABETIC RANGE

• DENTAL RANGE

• GARGLE

• GUM PAINT

• GYNAE PRODUCTS

• MOUTHWASH

• NASAL SPRAY

• NUTRACEUTICAL

• ORAL PASTE

• PEDIATRIC RANGE

• PPI & GASTRO

• SACHET

• SHOT

• SOFTGEL

• SOFT GELATIN

• SYRUP

• PHARMA TABLETS

• TOOTHPASTE

• COVID-19

• UNIQUE MOLECULES

• COSMETIC - Cipla: Cipla, a prominent Indian pharmaceutical company with a strong global presence in healthcare, is known by many. Started in 1935, it reigns as a manufacturer of various pharmaceutical products, such as drugs for respiratory, cardiovascular, and other therapeutic areas, which are affordable and accessible.

- Sun Pharma: A leading Indian multinational pharmaceutical company, Sun Pharma, became operational in 1983. It has a commendable record of making high-quality and non-expensive drugs in over 100 countries and thereby ranks in generics, specialty products, and APIs; at the center of dermatology, cardiology, and neurology.

- Alkem Laboratories: One of the top pharmaceutical companies in India, Alkem Laboratories was started in 1973. They are into manufacturing and marketing of generic, branded formulations, and API of good quality along with other therapeutic areas such as anti-infectives, gastroenterology, and pain management. Moreover, they are beneficial to the inhabitants of 50 countries worldwide.

- Zydus Cadila: Zydus Cadila, an establishment built in 1952, is among the important Indian businesses in the pharmaceutical field. The organization exports globally cost-effective and inventive healthcare solutions and is currently the most sought-after in the market sector. Its primary area of involvement is the production of generics, vaccines, biosimilars, and wellness products. Besides, the company is committed to inquiry and therapeutic interventions.

Factors to Consider When Choosing a Third Party Manufacturing Pharma Company

1. Certifications and Compliance

Make sure the manufacturer is GMP, WHO, and other regulatory standards compliant. Certification is the proof of their approach to quality.

2. Production Capacity

Appraise if the manufacturer can comply with your production conditions without compromising both timelines and quality.

3. Reputation and Experience

Collaborate with reliable and licensed third-party pharma manufacturers in India, and have a proven track record in the industry.

4. Cost and Terms

Discuss the pricing and make sure that your payment, delivery, and liability details are clear in order to avoid any disputes.

5. Customer Support

The reliable partner provides strong support, answers any inquiries, and guarantees the smooth communication process throughout.

“You May Also Like This:- In-Depth Guide to Tablet Production Process,,

How To Start Third Party Manufacturing Pharma?

A structured approach is required to ensure the success of third-party manufacturing in the pharmaceutical industry. The process begins with research and identification of potential manufacturers who can meet necessary standards and capabilities. A file is drawn up that lists prospective manufacturers; each one is then evaluated in turn on aspects such as reliability, production capacity, and regulatory compliance. Depending on the supply agreement, mutual negotiation about terms of sale, pricing, timelines, and quality standards follows. This agreement is finalized with formulation contracts, which represent the actual partnership. Close coordination throughout the production process ensures smooth operations and quality assurance.

Emerging Trends in Third Party Manufacturing Pharma

1. Specialized Formulations

The rapid evolution of healthcare has led the biologics, nutraceuticals, and injectables markets to be in great demand. Contract manufacturing pharma companies in India services are adapting to change in these specialized niches and are thus able to satisfy these needs.

2. Technology Integration

AI, IoT, and blockchain applications in the manufacturing industry are vital for the accuracy, cost-effectiveness, and transparency of the whole production and supply chain processes.

3. Global Expansion

Contracted pharmaceutical companies engaged in third party manufacturing in India are thrusting the global arena, providing their products to Europe, USA, and Africa at an affordable cost and of high quality.

Challenges in Third Party Manufacturing Pharma

The third party manufacturing pharma model is not without problems even though it has many positive characteristics:

- Regulatory Hurdles: This might be regarded as facing an extremely difficult problem of cross-border compliance with the needs of various countries.

- Quality Control: To ensure the same level of quality in every lot is in fact a vital issue.

- Communication Gaps: Misunderstandings between the participating parties can often lead to their serving as hindrances that provoke delays or mistakes.

How to Mitigate These Challenges

- Collaborate with well-known third party pharma manufacturers in India that have a well built up quality assurance framework.

- Carry out sustained and transparent communication to Summit the goals and expectations.

- Regular audits and inspections to ensure compliance and quality.

Conclusion

The third party manufacturing pharma industry is a part and parcel of the pharmaceutical ecosystem, providing a wide variety of advantages to the companies’ growth and cost-effectiveness. The collaboration with some of the top third party pharma manufacturers in India can take care of the quality factor, which in turn allows companies to explore and innovate new products and increase the size of the market. Being up to date is necessary for the industry to remain stable in the competition and for robust relationships that will help to establish.

FAQs

Both terms are usually used interchangeably however, the difference between contract manufacturing and third party manufacturing pharma is that contract manufacturing copmosise of a wider scope, which involves product development and supply chain management, whereas third party manufacturing pharma focuses only on production according to predefined specifications.

Research companies that have GMP and WHO certifications, look at reviews and client testimonials, and analyze their production capacity and expertise.

A wide range, including tablets, capsules, syrups, injectables, and specialized formulations like nutraceuticals and biologics.