- Insearch Formulation

- December 21, 2024

- 9:51 am

- No Comments

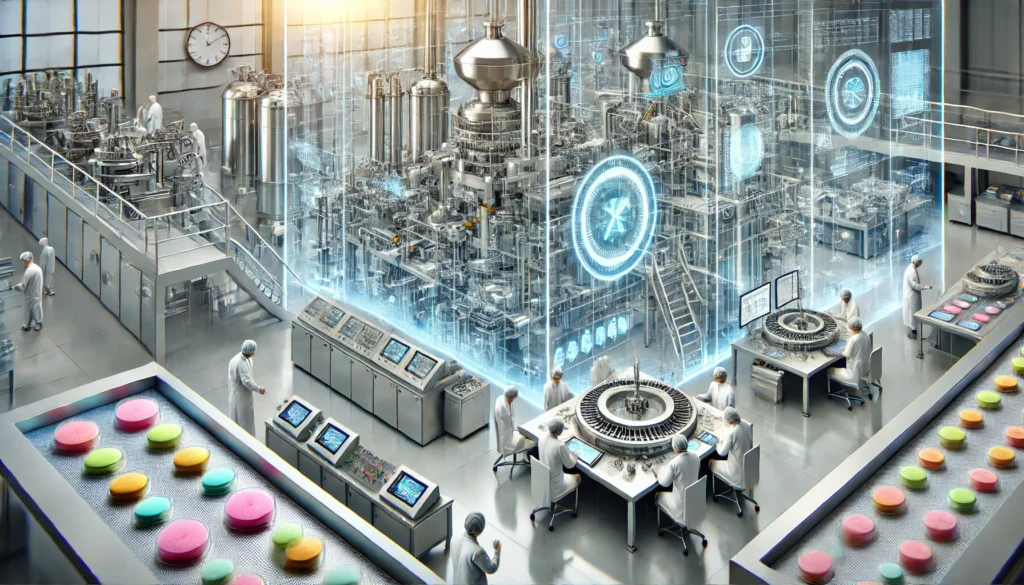

Introduction to Tablet Production

One of the main prescription methods, in pharmaceuticals, is tablet production. Tablet manufacturing is almost the most essential means of transportation of medications and plays an important role in their delivery. Tablet manufacturing is evolving largely in response to technology development and continuous improvement in quality assurance to ensure efficiency and consistency with precision. Tablets, as convenient, stable, and compact, are the leading form of drugs consumed in every part of the globe. This guide will take a deeper look at the tablet production process, including the necessary equipment, techniques, and challenges that companies face during tablet production.

Stages of Tablet Production

The tablet production is a manufacturing process that includes various interim steps, all created to guarantee the production of top-quality tablets. These are the primary stages:

1. Granulation Process in Tablet Manufacturing

Granulation is the first and the most pivotal step of the entire tablet-making process which involves the agglomeration of the powdered ingredients that lead to the formation of granules. This, in turn, enhances the flow properties and the compressibility of the materials. There are two main ways of granulation:

- Wet Granulation: A liquid binder is used to create granules.

- Dry Granulation: It is the mechanical force that drives the powder into granules without the use of liquid.

2. Blending

Later, the granules are with excipients such as lubricant, disintegrant and binders, are blended to ensure uniformity to the final product. Correct blending is extremely important to tablet formulation in order to keep the consistency constant in the final form.

3. Compression

The blended granules are then compressed into tables with the structural aid of a tablet press or tablet compression machine. This is when the compression stage is meticulously controlled so as to attain the desired hardness, size, and weight. Large-scale production usually tends to rely on high-speed tablet press machines.

4. Coating

The tablet coating process is a common process for the majority of the tablet type. Tablets are coated to make them more attractive, to protect them from the environment and to make them easier to swallow. The most common coating methods are as follows:

- Sugar Coating

- Film Coating

- Compression Coating

The choice of the coating is contingent on the required purpose of a tablet and the composition’s needs.

5. Quality Testing

Before the packaging can be finalized, the tablets are subjected to the most rigorous testing to ensure they conform to the accepted standards in the industry. Amongst them are:

- Hardness Test

- Friability Test

- Disintegration Test

- Dissolution Test

The idea of pain relief gels being liked due to their rapid action, localized treatment, and non-invasive application is prevailing. The best pain relief gel in India really acts on the affected area, thus going deeper in the tissues and put an end to the pain and inflammation that has been taking place. This kind of simplicity and quick effect makes them essential for numerous people.

Key Equipment in Tablet Production

For tablet production to be precise and efficient, specific equipment is used at various stages:

1. Tablet Compression Machines

Firstly, table compression machines are very important in tablet manufacturing. These are the applications of tablet compression machines:

- Single-Station Tablet Press: Useful for the production of small volumes only.

- Rotary Tablet Press: Excellent for fast high-scale production purposes only.

2. Granulators

The granulators are utilized during granulation in tablet manufacturing for the production of uniform granules that are essential for high-quality tablets.

3. Tablet Coating Machines

These machines act as tablets’ shellac deposit, making sure that the application is even and smooth.

4. Punches and Dies

The tooling and punches used in the tablet press determine the shape, size, and imprint of the tablets. Customized tooling options are available to meet design requirements.

You May Also Like This: – Which Oil is Best for Knee Pain Relief? Discover the Perfect Solution

Challenges in Tablet Manufacturing

The manufacturing process in the industry for tablets, as of today, is not without challenges such as:

- Sticking and Picking: It happens during the compression phase when granules are formulated wrong.

- Tablet Defects: Example cases are capping, lamination, and chipping.

- Dwell Time Issues: The problem is caused due to the lack of compression time that affects tablet integrity.

- Coating Defects: It appears as uneven coating or peeling.

To handle these challenges, one needs excellent skills in tablet formulation development and control of the relevant manufacturing parameters.

Steps Involved in Tablet Formulation

To be a successful and reliable tablet Production, one must go through a very deliberate development process. The central stages are:

- Picking up the main pharmaceutical ingredients (APIs).

- Election of the right excipients.

- Doing pre-formulations studies.

- Perfecting the granulation and blending processes.

- Modifying the compression parameters of a given product.

Importance of Quality Control in Tablet Manufacturing

Quality control is integral to the pharmaceutical tablet manufacturing process. Adhering to Good Manufacturing Practices (GMP) ensures:

Consistency in tablet quality.

Compliance with regulatory standards.

Prevention of defects and recalls.

Applications of Tablet Compression Machines

Tablet compression machines are versatile and widely used across the pharmaceutical industry for:

Producing different tablet sizes and shapes.

Developing coated and uncoated tablets.

Research and Development (R&D) purposes with specialized R&D tablet presses.

Emerging Trends in Tablet Manufacturing

The pharmaceutical industry is constantly innovating to make tablet production better. The trends that are currently emerging include the following:

- Continuous Manufacturing: Simplifies the production process.

- Smart Manufacturing: Includes the implementation of IoT and AI for real-time monitoring.

- Eco-Friendly Coating Materials: It is a method of lowering surplus waste.

Conclusion

In the tablet manufacturing process, you need to carefully monitor the condition of the equipment, the knowledge of the workers and the use of the state-of-the-art technology. The granulation process, the coating, and quality consciousness are of great importance in these products. Acquiring up-to-date equipment and following GMP can clearly elevate the production efficiency and quality.

FAQs

The sticking and picking problem is the most common, and it takes place as a result of poor formulation or unsatisfactory lubrication.

Some of the essential steps are granulation, blending, compression, coating, and quality testing.

On the one hand, tablet coating makes a tablet more visually attractive and on the other, it adds stability to the tablet and to protect it from the environment. It also increases patient adherence as the tablets are thus easier to swallow.